Extensive range of PE pipe and fittings for your electrofusion system

Bevo is a leading provider of electrofusion products for the aquaculture, biogas, agricultural and water management industries. Our range of electrofusion products is designed to offer reliable, efficient, and durable solutions for joining polyethylene (PE) pipes. Besides PE pipes and fittings, we also offer welding machines and the required tools, including scrapers and cleaning wipes.

Popular associated products

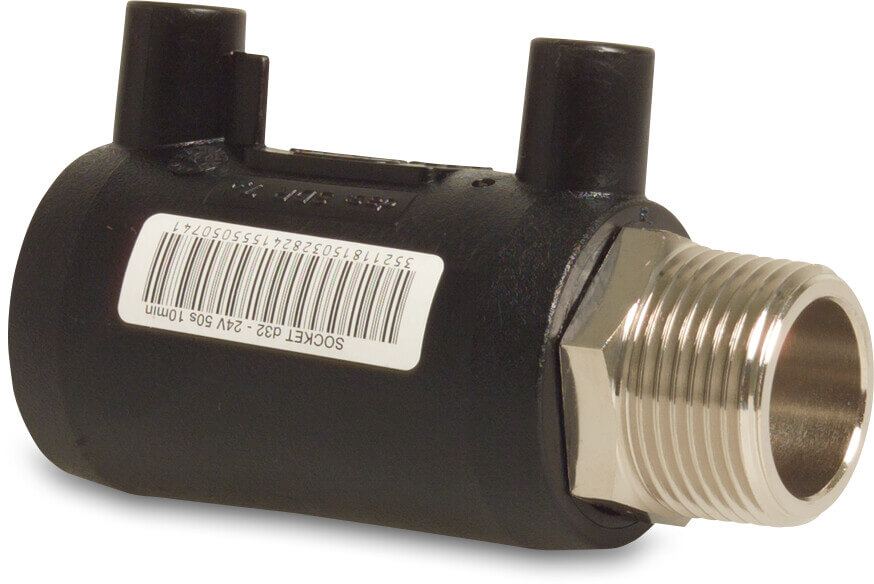

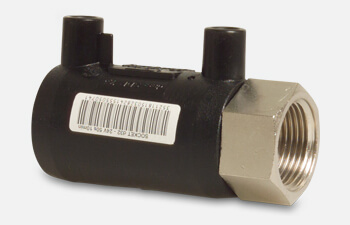

PE electrofusion fittings

Our wide range of electrofusion fittings ensures reliable and durable fusion joints when used in conjunction with electrofusion welding machines and polyethylene (PE) pipes. Available in various sizes up to 400mm to accommodate different diameters of PE pipes, in the pressure classes SDR11 and SDR17. The EF fittings comply with relevant industry standards, such as ISO 4427, ISO 1555, and local approvals like DVGW and WRAS.

PE pipe for electrofusion

PE pipes used for electrofusion should be made of high-quality PE material that is designed for fusion welding. The most common PE material used in electrofusion is PE100 (HDPE), which is widely used in water supply, and other applications. We offer our PE pipes range in size from 16mm to 1200mm or larger, and standard in SDR11 and SDR17 pressure classes. It is important to ensure that the SDR of the pipe and the electrofusion fittings are compatible.

PE welding machines and tools

Electrofusion welding requires specific machines and tools to properly fuse polyethylene (PE) pipes and fittings. We can offer all the key equipment and tools commonly used in electrofusion welding, including electrofusion welding machines, from simple versions to completely automatic welding units for diameters up to 630mm. We also stock cleaning tools, such as scrapers or cleaning brushes, used to remove any dirt, grease, or debris from the fusion surfaces of the PE pipes and fittings before welding.

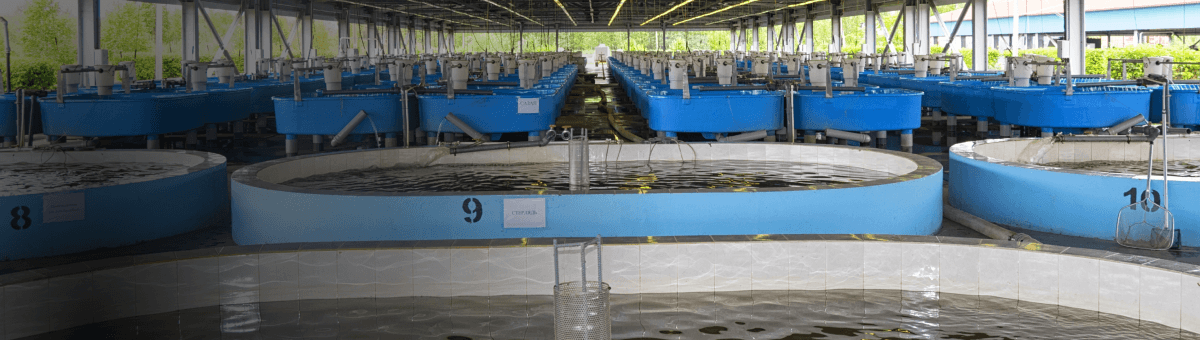

Electrofusion in aquaculture

Electrofusion offers several advantages in aquaculture, including strong and durable joints, watertight and airtight connections, versatility, cost-effectiveness, environmental friendliness, and quality assurance. These benefits make electrofusion a preferred method for joining HDPE pipes and fittings in aquaculture systems, helping to ensure reliable and efficient water management for fish health and production.

Electrofusion for Biogas

Electrofusion is favoured in biogas installations due to its gas-tight joints, corrosion resistance, versatility, efficient installation, quality assurance, and long-term performance. These benefits make electrofusion a preferred method for joining HDPE pipes and fittings in biogas systems, ensuring reliable and efficient gas management for renewable energy production. Want to know more, get in touch.

Industry

Electrofusion is used in a wide range of industrial applications where durable, reliable, and leak-free connections are required for joining HDPE pipes and fittings. Its resistance to corrosion, chemicals, UV degradation, and temperature fluctuation makes it a preferred method for joining HDPE materials in industrial processes, ensuring efficient and safe transport of fluids in various industrial settings.