Jason product groups

Jason compression range

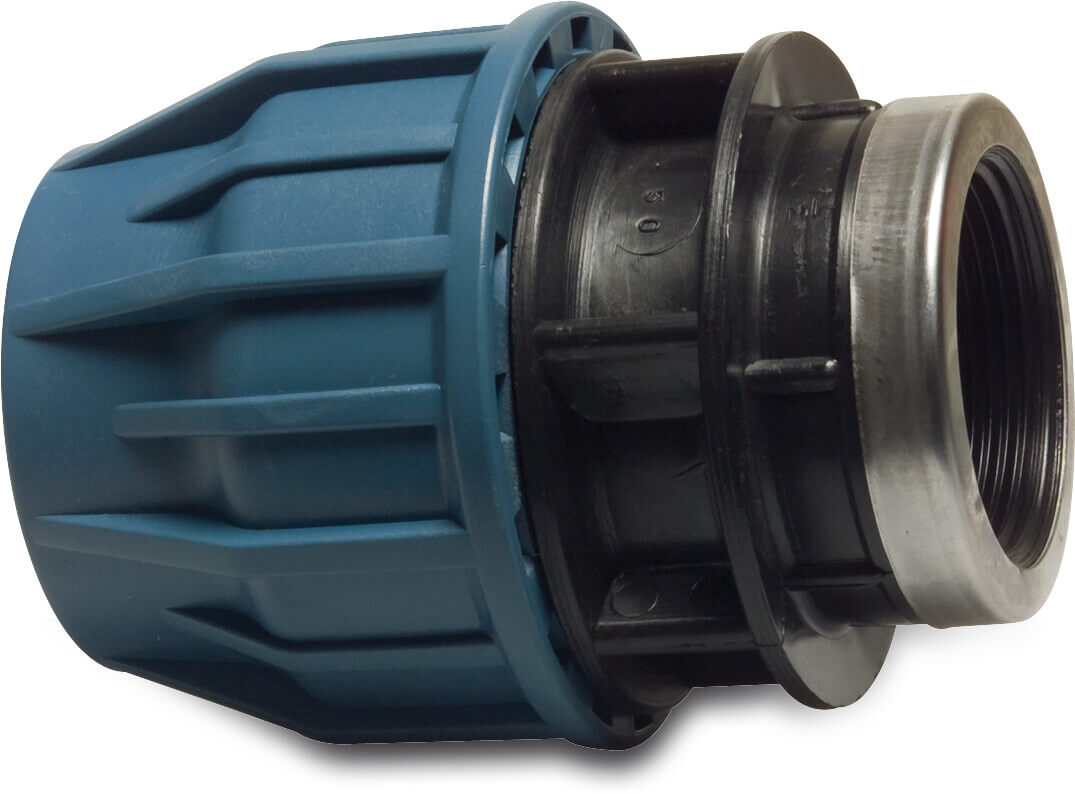

Jason offers a comprehensive range of fittings in multiple sizes for professional installations. Their compact design makes them easy to install, even in the smallest of spaces. Jason compression is compactible with all densities of PE pipe making them the versatile option.

View the product video to find out more reasons to choose Jason compression.

Jason solutions for your piping systems

We can offer everything you need for a reliable PE piping system. A wide range of PE pipes and fittings in different diameters, wall thicknesses and approvals to suit specific applications. Installation tools like scrapers and chamfers, as well as maintenance and repair products like repair clamps and saddles.

Connecting PE pipe

High-quality PE pipes of the appropriate size, pressure rating, and material specifications are the backbone of the piping system. Our assortment of pipes come in various types, such as PE80 or PE100, and are available in different diameters and wall thicknesses to suit specific applications. If required we can supply PE pipes with different drinking water approvals like WRAS, DVGW or KIWA.

Frequently Asked Questions

When are pp compression fittings the best choice?

- Non-critical pplications, such as irrigation systems, water supply lines, and drainage systems.

- Temporary or removable connections. They can be easily assembled and disassembled without damaging the pipes or fittings, making them suitable for situations where you may need to modify or reconfigure your piping system in the future.

What preparation is needed for installing PP compression fittings?

- Deburring and chamfering: After cutting the pipe, use a deburring tool to remove sharp edges and a chamfering tool to create a beveled or chamfered end. These processes are essential for improving safety, preventing injury, and ensuring proper fit and functionality of pipe connections.

- Check for leaks: After tightening the compression nut, visually inspect the joint for any signs of leakage. Monitor the connection for a period of time to ensure there are no leaks or drips.

When are PP compression fittings not the right choice?

Which features are important for PP compression fittings?

- Sealing gasket: A sealing gasket is often integrated into PP compression fittings to ensure a watertight seal. The gasket should provide reliable sealing under pressure and be resistant to degradation from chemicals or UV exposure.

- Threaded nut: The threaded nut is used to tighten and secure the compression fitting onto the pipe. It should be easy to grip and turn, allowing for proper installation without the need for excessive force or specialised tools.

- Ease of installation: Jason compression fittings are known for their ease of installation. Their user-friendly design allows for simple and efficient installation without the need for specialised tools.

What are the key advantages of compression fittings?

2. Versatility: Compression fittings are compatible with a wide range of pipe materials, including copper, PVC, PEX, and polypropylene

3. Leak-free connections: When installed correctly, compression fittings provide reliable and leak-free connections. The compression nut creates a tight seal between the pipe and the fitting, preventing water or gas leaks.

4. Disassembly and reusability: Compression fittings can be easily disassembled and reassembled without damaging the fitting or the pipe.

Can I glue PE pipes and fittings?

Frequently Asked Questions

- Non-critical pplications, such as irrigation systems, water supply lines, and drainage systems.

- Temporary or removable connections. They can be easily assembled and disassembled without damaging the pipes or fittings, making them suitable for situations where you may need to modify or reconfigure your piping system in the future.

- Deburring and chamfering: After cutting the pipe, use a deburring tool to remove sharp edges and a chamfering tool to create a beveled or chamfered end. These processes are essential for improving safety, preventing injury, and ensuring proper fit and functionality of pipe connections.

- Check for leaks: After tightening the compression nut, visually inspect the joint for any signs of leakage. Monitor the connection for a period of time to ensure there are no leaks or drips.

- Sealing gasket: A sealing gasket is often integrated into PP compression fittings to ensure a watertight seal. The gasket should provide reliable sealing under pressure and be resistant to degradation from chemicals or UV exposure.

- Threaded nut: The threaded nut is used to tighten and secure the compression fitting onto the pipe. It should be easy to grip and turn, allowing for proper installation without the need for excessive force or specialised tools.

- Ease of installation: Jason compression fittings are known for their ease of installation. Their user-friendly design allows for simple and efficient installation without the need for specialised tools.

2. Versatility: Compression fittings are compatible with a wide range of pipe materials, including copper, PVC, PEX, and polypropylene

3. Leak-free connections: When installed correctly, compression fittings provide reliable and leak-free connections. The compression nut creates a tight seal between the pipe and the fitting, preventing water or gas leaks.

4. Disassembly and reusability: Compression fittings can be easily disassembled and reassembled without damaging the fitting or the pipe.